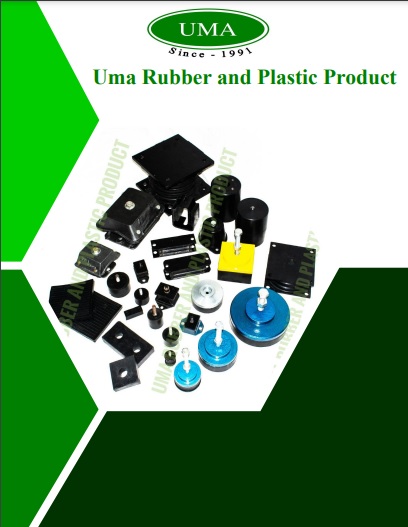

About UMABOND

UMABOND came into operation in year 1991 with the aim of manufacturing superior quality of industrial rubber products.

Today, with decades of experience , UMABOND is one of the leading manufacturer , supplier and exporter of rubber products.

UMABOND have a full facilitate in-house plant from proccesing raw material to achieving superior quality of final product and then after performing all neccesary testings.

With the vision of constant improvement philosophy , we always appreciate to hear from clients and give our best to fulfilment their requirements.

UMABOND today owe all success to its pre-eminent team.

Achievement Map of UMABOND

1991

Jignesh Pated founded UMABOND by borrowing Rs 5,000 with one single hand press and started doing Job Work.

1996

Entered Irrigation Rubber Product Segment.

2001

Invested in the first hydraulic press.

2005

Implemented automatic PLC-based machines to maximise production.

2010

Diversified into manufacturing anti-vibration mounts.

2012

Established a PAN India presence.

2014

Expanded into extrusions in Natural, Nitrile, and EPDM.

2018

Kevin Patel, son of Jignesh Patel, joined the business.

2019

Established a Sales and Marketing Office.

2020

Set up a Compounding Unit.

2020

Expanded into international business.

2021

Partnered with a Machining Unit, which including VMC, CNCs, Lathes, CNC Wirecut, etc.

2021

Introduced Silicone Extrusions.

2022

Initiated R&D in Silicone Polymer Synthesis.

2024

Establishing a sales unit in the USA.

By 2030, UMABOND aims to be one of the largest Industrial and Commercial (Non-tyre) Rubber Products Manufacturing Companies with sustainable developments.

Testing Facility and Testing Resources at UMABOND

UMABOND do not satisfy just by shaping the polymer; we transcend product properties, crafting a distinctive line that exceeds conventional standards.

A well-equipped rubber testing lab plays a crucial role in helping UMABOND to ensure the quality and performance of its rubber products. Here’s how a rubber testing lab contribute to the process of testing and perfecting products at UMABOND:

Quality Assurance

The testing lab and Resources allows UMABOND to conduct comprehensive quality assurance tests on raw materials and finished rubber products. This ensures that only materials meeting specified standards are used in production and get delivered.

Process Control

Our lab and Resources facilitates control over the manufacturing process by conducting tests at various stages, from processing raw materials to achieving the final product. This helps identify and address any issues early in the production cycle.

Product Development

UMABOND use the testing lab to assess the performance of new rubber formulations and prototypes. This aids in the development of new and improved products by fine-tuning the material composition and manufacturing processes.

Compliance with Standards

Our lab and resources allows UMABOND to conduct tests in accordance with relevant ASTM and industry standards. Compliance with these standards is essential for product certification, meeting regulatory requirements, and ensuring customer satisfaction.

Identification of Weaknesses

Through various tests, our lab and resources helps identify weaknesses or potential issues in rubber products, such as poor abrasion resistance, inadequate tensile strength, or susceptibility to environmental factors like ozone or UV radiation.

Constant Improvement

The lab aligns with UMABOND's vision of constant improvement by providing data and insights that can be used to enhance product quality. Feedback from tests allows for continuous refinement of formulations and manufacturing processes.

Customer Satisfaction

Testing ensures that rubber products meet or exceed customer expectations in terms of performance, durability, and safety. This contributes to customer satisfaction and helps build a positive reputation for UMABOND in the market.

Problem Resolution

If issues arise in the production process or with the final products, the testing lab helps diagnose and resolve problems. Root cause analysis through testing assists in implementing corrective actions.

Cost Savings

Early detection of material or process issues through testing lead to cost savings by preventing the production of defective or substandard products, reducing waste and rework.

Benchmarking Against Competitors

UMABOND use the lab to benchmark its products against those of competitors. This helps identify areas where improvements can be made to gain a competitive edge in the market.

Below are the methods and standards on which UMABOND rely,

ASTM D2240 : For testing hardness on the Shore A scale.

ASTM D412 : For testing tensile strength, elongation and modulus of vulcanized rubber.

ASTM D297-15, Method A : For determination of total solids which includes moisture, volatile matter and ash.

ASTM D297-15, Method B : For determination of Volatile Matter

ASTM D297-15, Method C : For determination of Ash Content

ASTM D297-15, Method D : For determination of Waxes

ASTM D297-15, Method E : For determination of Insoluble Sulfur

ASTM D2632-15: For resilience by vertical rebound

ASTM D1149-07(2013) : Ozone Resistance Testing :For determination of cracking in an ozone controlled environment.

ASTM D4329 : UV Resistance Testing: For determination of effect on rubber when exposed to fluorescent lamp.

ASTM D573: Heat Resistance Testing by Deterioration in an Air Oven

ASTM D2137 : Low-Temperature by Determination of Brittleness Point of Flexible Polymers and Coated Fabrics

ASTM D5470 : For Determination of Thermal Transmission Properties of Thermally Conductive Electrical Insulation Materials : While primarily designed for electrical insulation materials, but we do adapt this standard for measuring the thermal conductivity of certain rubber materials.

ASTM D5963 :For determination of abrasion resistance by Rotary Drum Abrader.

For electric conductivity testing of rubber, there isn’t a specific ASTM standard dedicated solely to this purpose. However, there are ASTM standards that provide guidance on electrical testing of rubber materials, and these standards can be adapted for measuring electric conductivity.

ASTM D991 : For volume resistivity of Electrically Conductive and Anti-Static Products.

ASTM D150 : For determination of AC Loss Characteristics and Permittivity(Dielectric Constant) of Solid Electrical Insulation.

ASTM D635 : For determination of Rate of Burning and/or Extent and time of burning in a horizontal position.

We are equipped with various calipers, micrometer, Bore Gauge, etc for dimensional and visual Inspection.